NomoFlow™ Platform

The Operating System for Diagnostic Certainty.

A fundamental redesign of the lateral flow manufacturing process, engineered to eliminate variability and create a new standard of reliability.

The Challenge: The Hidden Variability in Every Test.

Traditional lateral flow assay manufacturing, despite best efforts, is susceptible to microscopic inconsistencies—in materials, in reagent deposition, in environmental conditions. These variables, often invisible, can lead to frustrating lot-to-lot performance shifts that undermine clinical confidence. We decided this was an unacceptable variable in the equation of animal health.

The Four Pillars of NomoFlow™

-

1. Advanced Material Science & Informatics

-

Our process begins with the rigorous characterization and selection of nitrocellulose membranes and conjugate pads. Each lot of raw material is digitally fingerprinted, and our informatics system tracks its performance characteristics, ensuring only materials that meet our exacting specifications enter the production line.

-

2. Precision Micro-Jetting & Deposition

-

Replacing traditional 'dip-and-dry' methods, NomoFlow™ utilizes non-contact, piezoelectric jetting to deposit nanoliter-scale droplets of antibodies and antigens. This digitally-controlled process ensures a level of uniformity and precision in the reaction zones that is unattainable with conventional methods.

-

3. Controlled Microfluidic Dynamics

-

The physical design of our cassettes and the controlled porosity of our materials are engineered as a single system. This optimizes capillary flow dynamics, ensuring a consistent sample migration speed and reaction time, which is critical for both accuracy and run-to-run consistency.

-

4. Automated In-Line Metrology

-

At multiple stages of production, machine vision systems and optical sensors measure critical parameters in real-time—such as line integrity and signal intensity. This 100% in-line inspection, not batch testing, allows us to identify and reject microscopic deviations before a test is ever assembled.

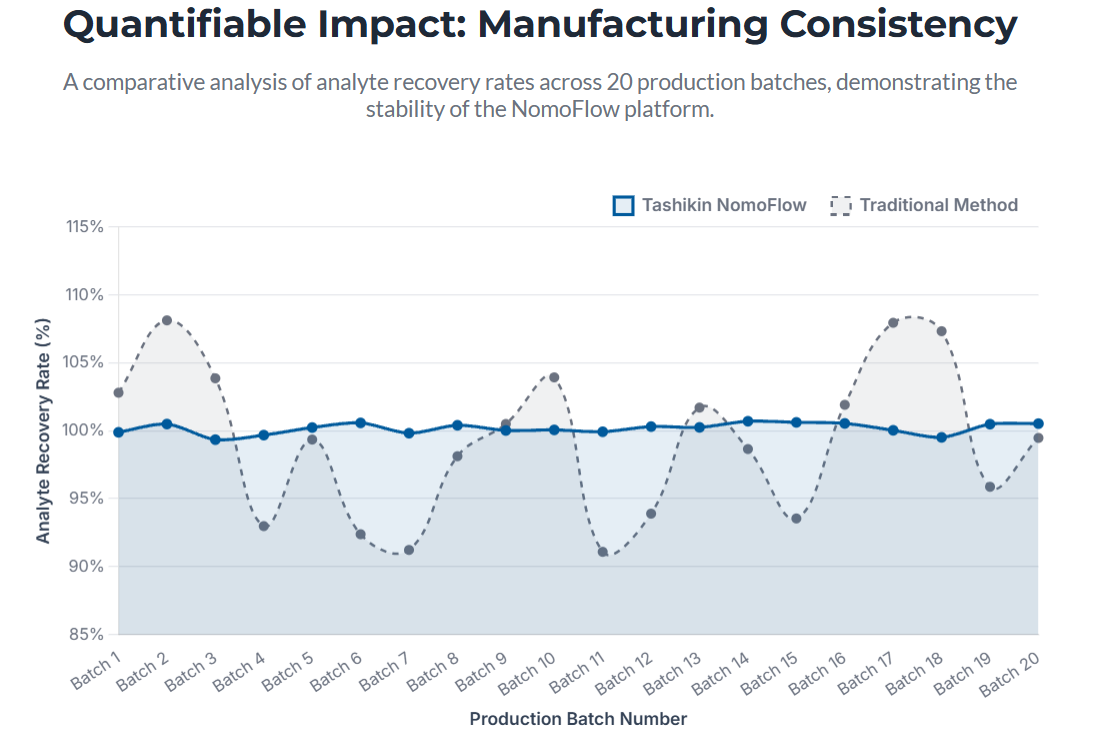

The Result: Quantifiable Consistency.

The output of the NomoFlow™ engine is a diagnostic tool with industry-leading lot-to-lot consistency. The chart illustrates the tight coefficient of variation (CV) of a typical Tashikin assay run across multiple, independent production lots compared to a traditionally manufactured assay.

A Platform for What's Next.

NomoFlow™ is more than a manufacturing process for today's tests; it's a scalable platform for future innovation. The precision and control it provides are the foundation for developing next-generation diagnostics, including ultra-sensitive assays, quantitative tests, and complex multiplex arrays.

See the results of our obsession.

Explore the portfolio of products built on the NomoFlow™ platform.